Manufacturers, Suppliers And Exporters Of ZERO HOLD UP FILTER PRESS

The liquid is directed with the help of pumps through the center channel of the cartridge from the bottom of the body. Suspended particles get retained on the filter medium resting on the filter plates and the clear filtrate emerges from the side holes of the plates inside the tank and flows out from the bottom outlet. The filter tank does not come into contact with the liquids and hence remains clean. The cake filtrates and solids remain completely inside the fully closed filter plate cartridge. Complete recovery of the filtrate is possible by passing of air or an inert gas through the bottom inlet to dry the cakes and get a clean empty tank.

SALIENT FEATURES

• Maintenance can be easily carried out just by lifting the dome i.e., without lifting the cartridge.

• Quick and easy removal of filter plate cartridge. for cleaning of cake.

• Filtrate is obtained without scavenging agents.

• Liquid does not remain between the tank or the cartridge.

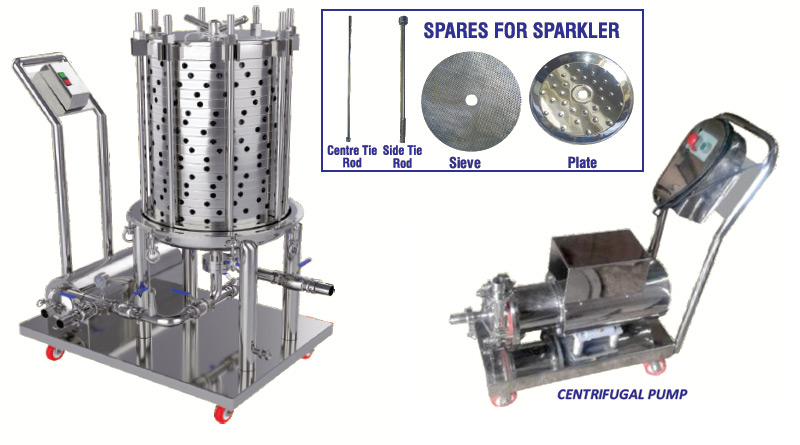

• Special pumps available to meet viscos and critical products to be filtered achieved with help of gear pump / centrifuge pump/Lobe pump.

• Uniform distribution of cake and filtrate.

• Back wash facility available to make the solids free for any impurities.

• Sizes available 8", 14" & 18" diameter.

• MOC SS 316 / 316L.

• Available with centrifugal / gear / lobe pump.

• Fitted with pressure gauge, safety valve & airvent.

• cGMP with documentation.

| Model | PE-08 | PE-14 | PE-18 | PE-24 | |||||||||||

| Plate Diameter | 8” | 14” | 18" | 24” | |||||||||||

| No. of plates | 6 | 8 | 8 | 10 | 12 | 10 | 12 | 15 | 24(s) | 15 | 18 | 24 | |||

| Filtering Area(m2) | 0.217 | 0.279 | 0.819 | 1.001 | 1.183 | 1.65 | 1.95 | 2.40 | 3.75 | 4.126 | 5.035 | 6.625 | |||

| Cake holding Capacity Ltrs. | 4.9 | 6.3 | 24.57 | 30.25 | 37.75 | 55 | 65 | 80 | 125 | 144 | 171 | 225 | |||

| Flow Rate/Hr. | 600 | 800 | 1500 | 1700 | 1900 | 4000 | 4600 | 5500 | 8200 | 7OOO | 8500 | 12500 | |||

| Flow Rate/Hr. | 600 | 800 | 1500 | 1700 | 1900 | 4000 | 4600 | 5500 | 8200 | 7OOO | 8500 | 12500 | |||

| Pump Size & Power | ½” / 1HP | 1” /2HP | 1 1/2" / 3HP | 1 1/2" 5HP | 2” /5HP | ||||||||||